What do you think about when we mention chain? Perhaps the chain on a bike or motorbike to transmit power to the wheel. Or you may think of the old unit of measurement called a Chain. When talking about the chain making industry, we mean a series of interlocking rings or ovals that can be used for retaining, binding, holding or supporting objects.

Chains on ships are referred to as “Cables”. This is a nautical term that goes back to the days when hemp rope was used for securing ships. So when you see the word “Cable” used on this site, don’t think of the kind of cable used to carry electricity. Think about the chains used to secure a ship to the dockside, or to lower the anchor to the seabed to stop the ship drifting with the tide.

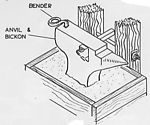

Chain has been made by humankind for thousands of years, ever since we discovered how to make and form metals into shapes. Chainmaking was done by the local Blacksmith, and his chains would have been used for agriculture, particularly the harnessing of large animals and for pulling equipment. Ships, however, had long used hemp rope to secure them to the dockside, or to support the anchor. The problem with hemp is that it rots over time, particularly when immersed in water for long periods. It also is prone to being cut by sharp objects such as rocks, or by simply being rubbed on the side of the ship.

Documentation exists from several hundred years ago, which mentions defence chains being placed across harbour mouths and supported by barges in order to prevent enemy ships from entering. It was during the early part of the nineteenth century that the Navy began carrying out trials on the “new” iron cable-chain. Much of the hemp had to be imported and this was contributing to soaring prices, so it is not surprising that the Navy was keen to find an effective alternative.

The best metal for making chains is wrought, or puddled iron, as it is capable of withstanding sudden shock loads without cracking or breaking, unlike cast-iron which is brittle. Around the late eighteenth century pit shafts were becoming much deeper in order to make best use of the available coal-seams, and objects being cast in foundries were becoming much larger and heavier. Hemp rope had become inadequate for the tasks for which is was being employed. Gilbert Gilpin, chief clerk to Wilkinson at the Bersham Ironworks near Wrexham, noticed that iron chains were being used with mixed results for winding up the pit shafts. After spending a short time at the Soho Manufactury of Boulton and Watt in Birmingham, he moved to South Wales, where he became interested in the method of making wrought iron by the puddling process being used by Henry Cort. Two years later he was in Shropshire working at the Old Park Ironworks of Botfield and Son, where he put his knowledge of the Cort method of puddling iron to good use. In his spare time he began experimenting with the use of chain for winding up the shafts at local collieries. A move to the Stirchley furnaces of the Botfield Company near Shifnal did not prevent him from continuing his experiments, and in 1805 he was awarded a silver medal and 30 guineas for the work he had done on perfecting iron chains. In 1807 he left Botfields and set up his own works in Coalport, making chains for use in the pits and on cranes.

The making of the first cable-chain in this country is credited to Robert Flinn at his workshop in South Shields in the year 1808, although cable-chains were certainly in use in France prior to this date. According to the “History of the Royal Navy,” edited by Peter Kemp, on 21st August 1801, Lord Nelson attempted to cut loose Bonaparte’s fleet from it’s mooring at Boulogne. The attempt failed as the enemy ships were moored using the “new-fangled chain cables instead of the more usual rope”.

The first iron cable-chain made in this country was for use on the 221 ton vessel, the "Ann and Isabella". Its effectiveness was proven when, during a severe winter storm, when several other ships using hemp cables were made fast to her, the iron cable held fast whilst the hemp cables were cut through by pieces of floating ice.

The Navy was impressed with reports received about the effectiveness of iron cable-chain, particularly when used for restraining ships at anchor during storms. Over the next few decades confidence grew in the use of iron cables, and so their use was extended until they entirely replaced hemp.

The merchant fleets were slower in adopting iron cable as the insurance companies imposed a premium on policies for ships using them. However, once it became apparent that iron cables out-performed hemp, the premium was removed and iron cable-chains replaced hemp.

The chain making industry would now develop into a major enterprise, with Britain the leading exponent.

Rollover the captions in the box to see the available images in thumbnail format, click the caption to see the full-size image

| Reference: | 656 |

| Keywords: | |

| Archive Ref: | |

| Updated: | Thu 17 Apr 2008 - 1 |

| Interpretation written by | Louis Howe |

| Author's organisation | Curatorial |

| Organisation's website | |

| Contributor | |

| Contributor | |

| Contributor |