Matchbox-making

Matchbox-making A Slipper-maker's home, drawing by Piffard

A Slipper-maker's home, drawing by Piffard A Jewish slipper factory, drawing by Piffard

A Jewish slipper factory, drawing by Piffard Part of the process in slipper making, drawing by Piffard

Part of the process in slipper making, drawing by Piffard Sweated worker and middleman, drawing by Piffard

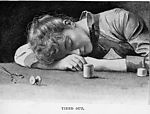

Sweated worker and middleman, drawing by Piffard Exhaustion was a way of life, drawing by Piffard

Exhaustion was a way of life, drawing by Piffard

Whatever the trade, the story of "home-sweating" is the same. Anything between one and ten people crammed into a poorly ventilated room, working long hours for low pay. Whenever part of a manufacturing process was sub-contracted to out-workers, the possibility of sweating arose. Home-workers had to rely on a go-between, known as a middleman or "fogger", to hand out the work sub-contracted by the larger manufacturers.

Box-making is one of many examples where a middleman operated. Boxes were stored in flattened form at a warehouse. Manufacturers waited until orders came in before getting them made up. This work was sub-contracted out to middlemen, who took materials out to the home-workers and paid them for finished work.

Middlemen took a percentage of the money the manufacturer was willing to pay to the home-worker. In the chain-trade this was usually 25%. The situation was even worse if the middleman was dishonest, and misled the home-worker about the rates of pay the manufacturer was offering.

Tailors highlighted this situation when giving evidence to the House of Lords Select Committee on the Sweating System (S.C.S.S.) They said that a price for a particular job would be agreed at the start. Then after the work was done, they found the middleman would not pay the agreed price. Excuses would range from there being a glut in the market, to the manufacturer having to cut their prices as a result of competition. At this point, they had little choice but to accept what the middleman was offering. Starvation was the only alternative.

Britain was one of the richest nations in the world, and yet "sweated" labour existed at the bottom of almost every trade. Tailoring included all types of clothing from commonplace shirts and trousers, to riding clothes, ceremonial robes and government contract work such as military uniforms. In each case some part of the process was carried out by sweated workers.

The manufacture of umbrellas, toys, waterproof clothing, lace, nails, chains, shoes and slippers and even furniture were all produced under sweated conditions at some point in the process. Leatherwork, such as making parts for harnesses, was commonly sweated. Witnesses to the S.C.S.S. told of harnesses made for the army that were so shoddily made that they would fall apart in use. The fault may not have been with the home-workers, but with the middlemen, who would have driven them so hard that there was an inevitable drop in quality.

It was not only poor pay that home-workers had to suffer. Frequently, these trades would involve the use of unpleasant and dangerous chemicals or heat from gas-burners, which would create a bad atmosphere and make people ill. During the Nineteenth Century the Factories Acts had improved working conditions for millions of people, as well as protecting children from exploitation. Unfortunately, they did not apply in the home, so there were no inspectors to ensure satisfactory working conditions. This situation perpetuated the downward spiral of poor conditions, low pay, and ill-health.

Rollover the captions in the box to see the available images in thumbnail format, click the caption to see the full-size image

| Reference: | 726 |

| Keywords: | |

| Archive Ref: | |

| Updated: | Wed 25 Jun 2008 - 1 |

| Interpretation written by | Louis Howe |

| Author's organisation | Curatorial |

| Organisation's website |